Stock Removal Strategies in Odoo-15

In warehouse operations, removal techniques are used to choose the best products depending on certain criteria. There are four types of Stock Removal Strategies in Odoo-15: FIFO, LIFO, FEFO and closest location. These strategies help to manage stocks efficiently.

Types of removal strategy

- FIFO (First In First Out) – the first stocked product will be moved first.

- LIFO (Last In First Out) – the products which are brought in the last will be moved out first.

- FEFO (First Expiry First Out) – the products are moved based on their expiry date.

- Closest Location – products are moved from the closest location.

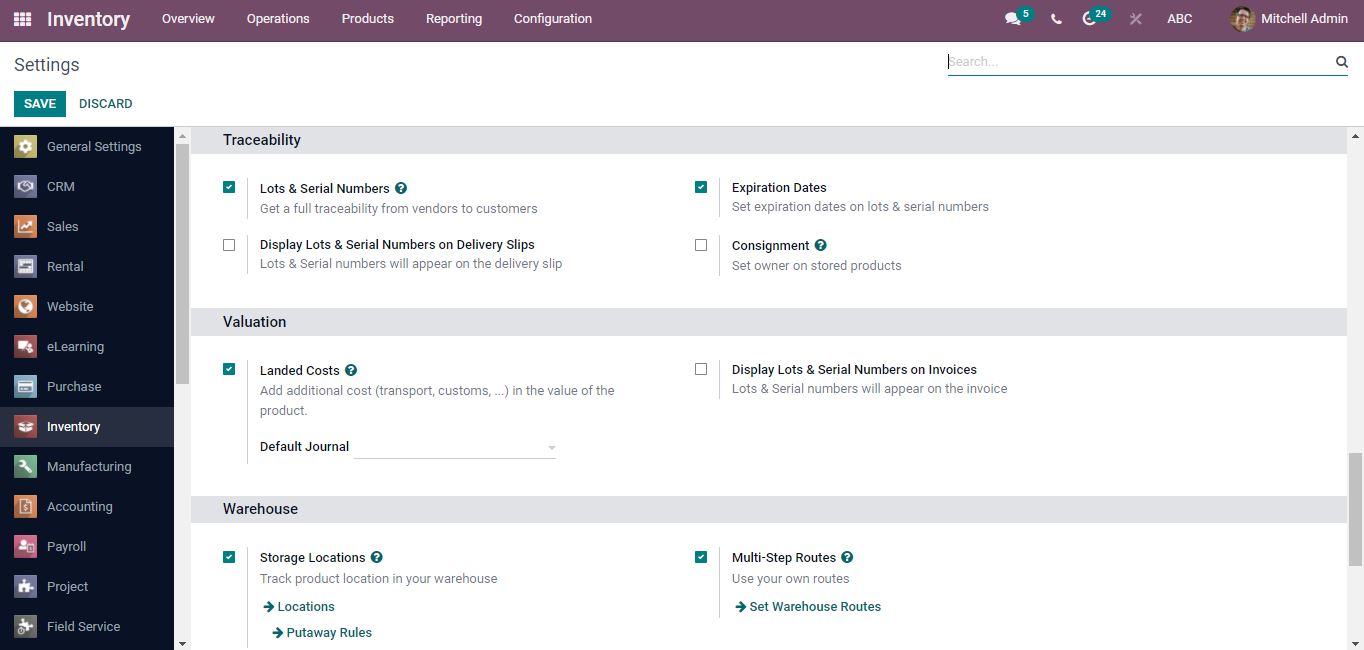

Configuration => Settings

Enable Storage locations and Multi-Step Routes under the warehouse for managing several storage locations and specific product moving routes. Lots and Serial Numbers, or even the Expiration Dates option, should be enabled in order to complete the inventory management by assigning lots and serial numbers, and also estimating the product’s expiration date.

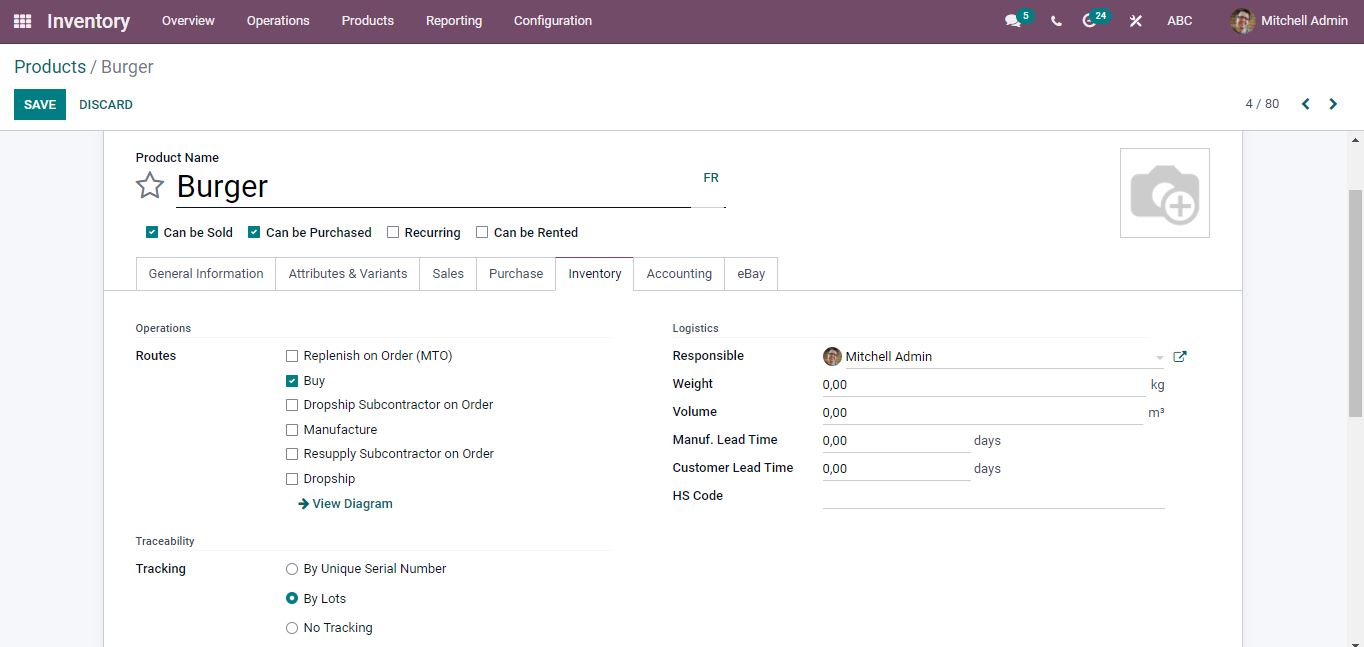

Products

Create a new product which is storable type and under the inventory tab make the tracking as by Lots. Once you’ve finished filling the details, click the Save button.

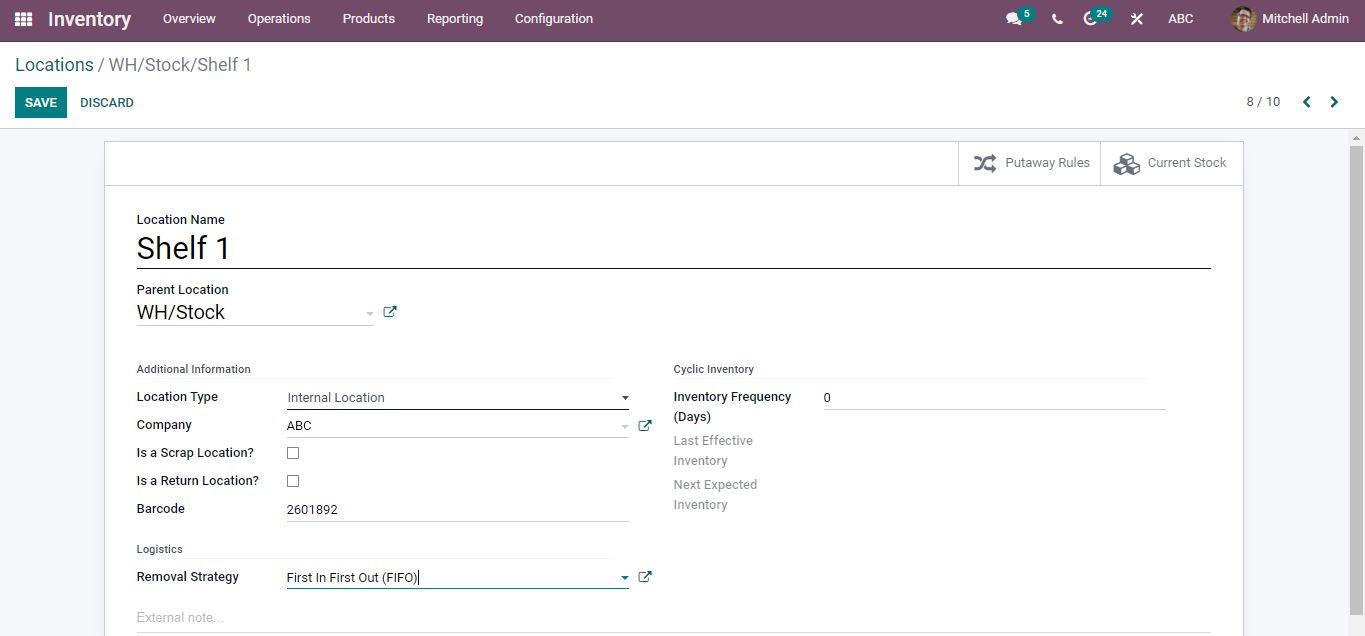

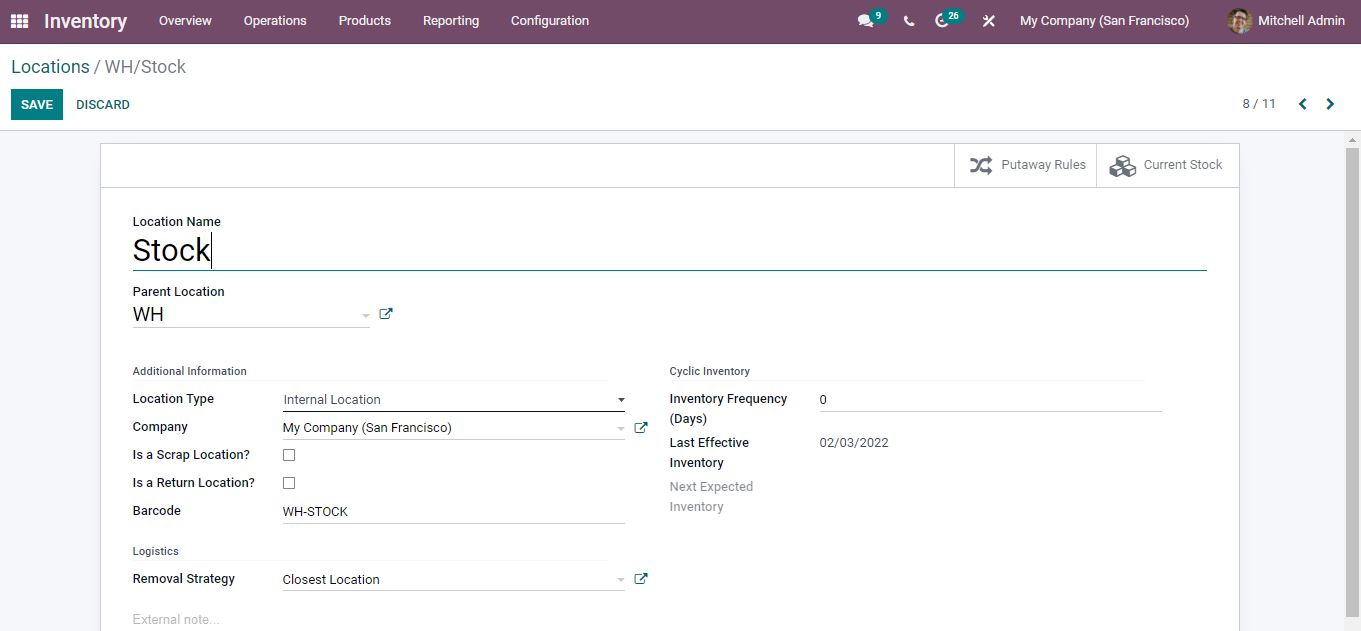

Configuration => Locations

- First In First Out (FIFO)

Select the location for the product from the list or create a new location.

Opening the location, under the logistics the Removal Strategy can be set to First in First Out which ensures that the product that is stocked first will be removed first.

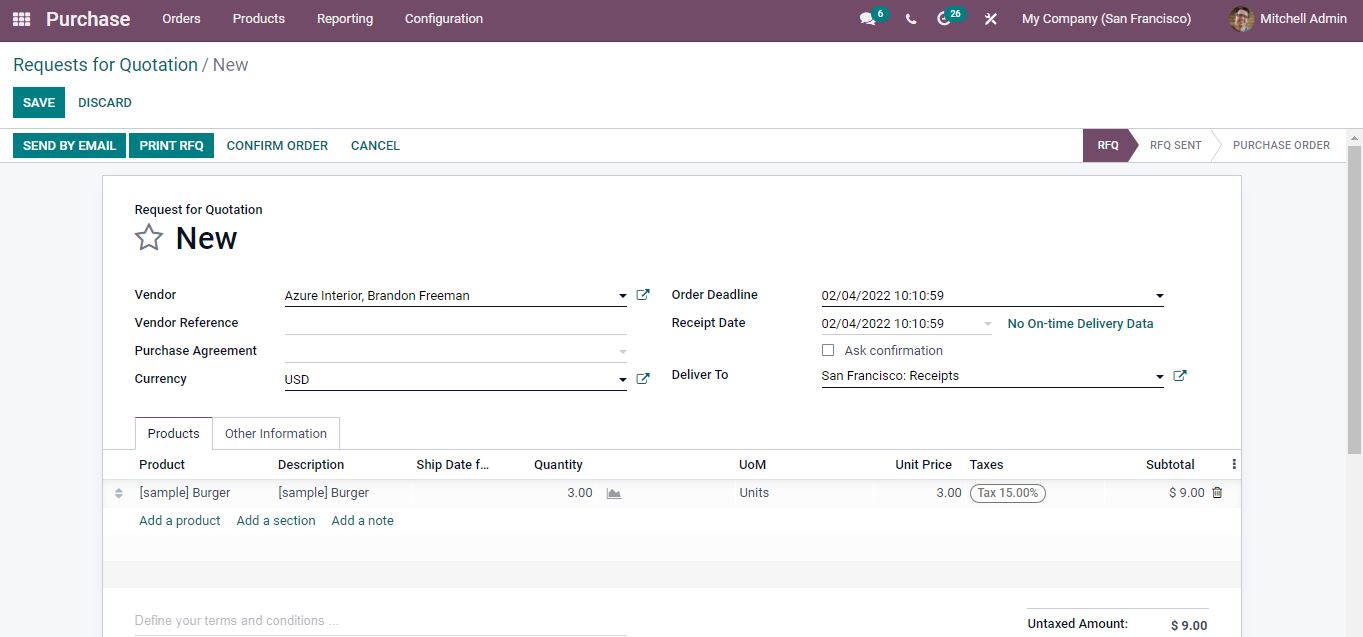

Create a Purchase order

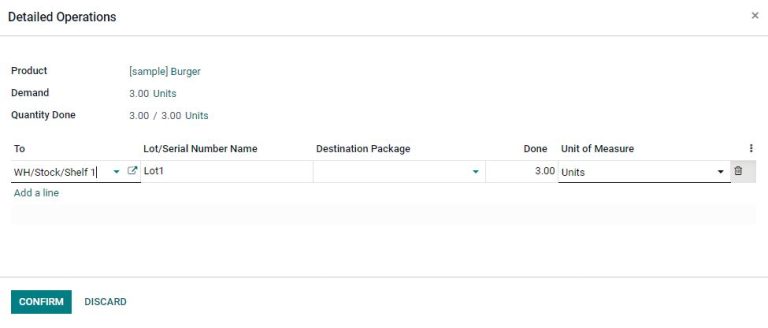

Add the vendor details, products and the quantities required. Confirm the order after filling in all the details and then receive the products. Before you validate assign the Lot numbers for the purchase.

Lot/Serial numbers are used for tracing so that the products should be assigned with the appropriate lot/serial numbers.

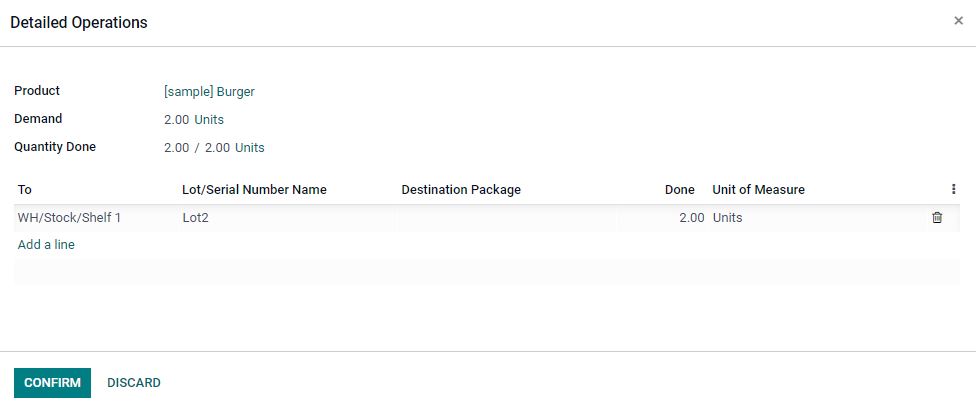

Confirm the lot name and then validate the purchase. Create a new purchase order for the same item for another two quantities and assign lot numbers before validating.

After confirming the lot numbers validate the purchase order.

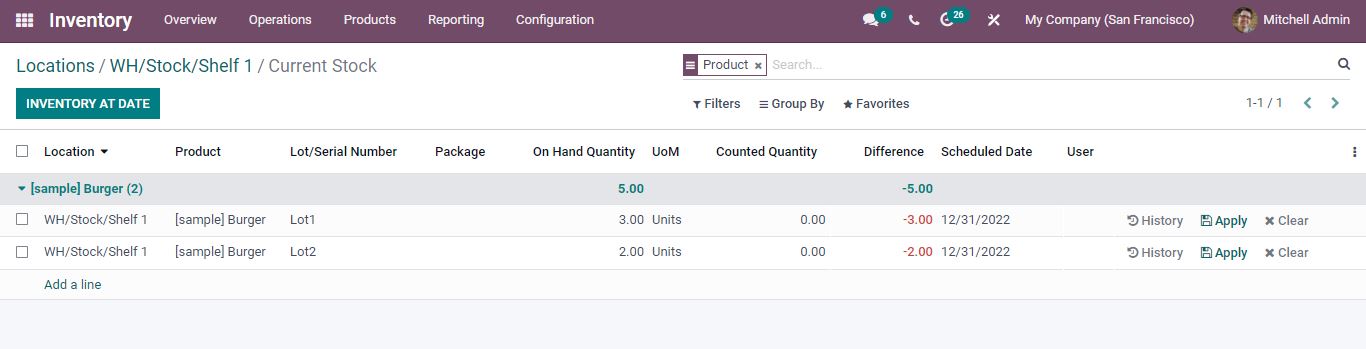

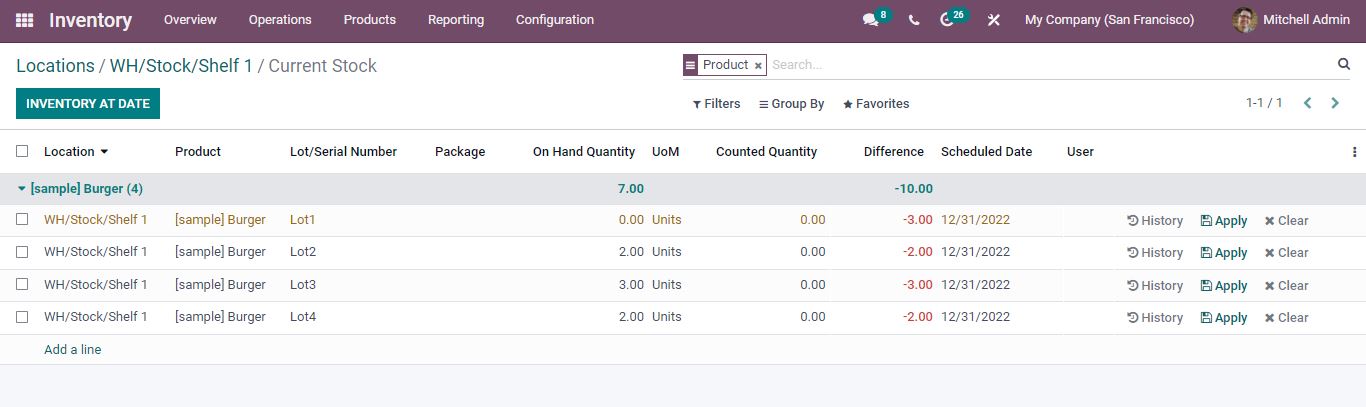

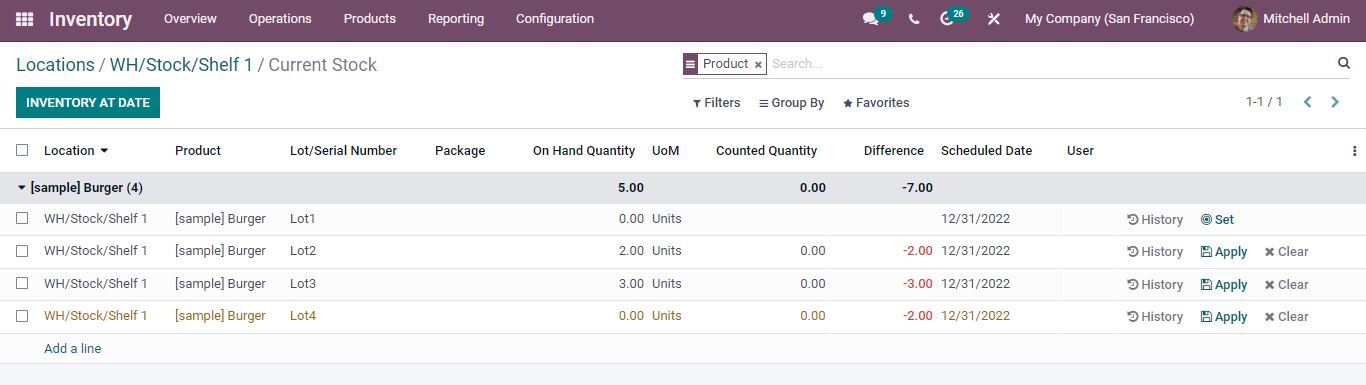

Inventory => Configuration => Location

The Stock will be added to the respective location under the current stock. The Serial Number and Lot Number defined will help us to understand the product’s Stock information.

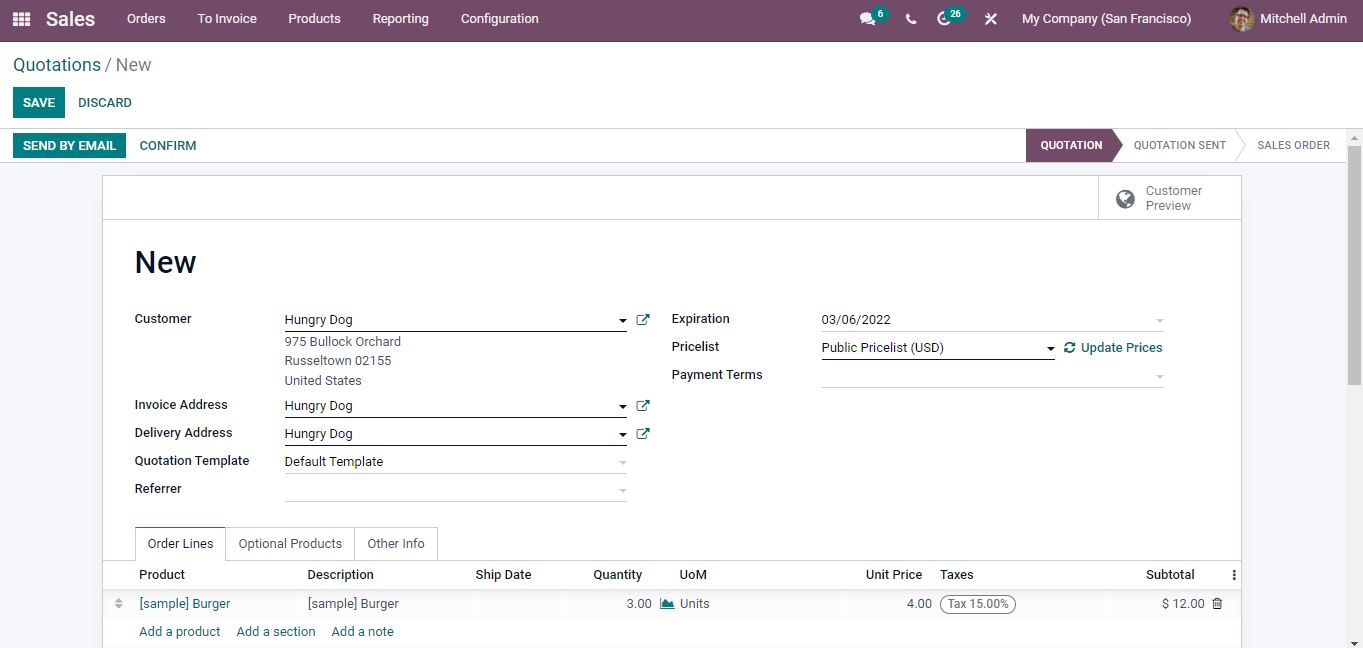

Sales Order

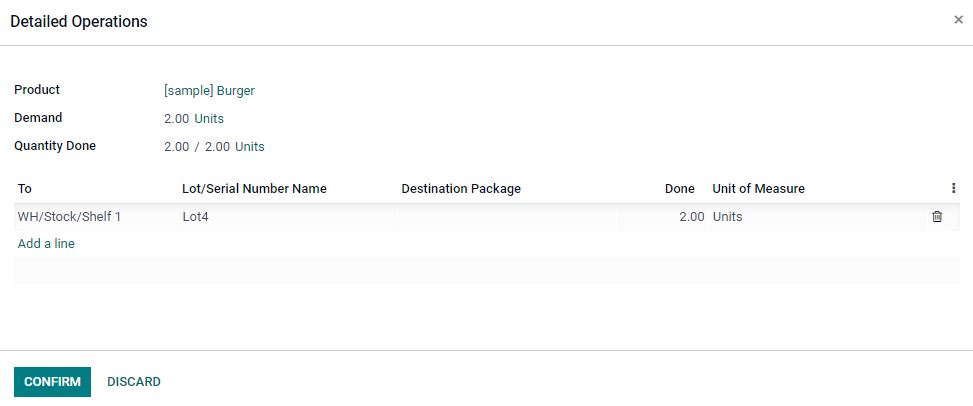

A Sales order is prepared for the same product of quantity three, the Lot and Serial Numbers are then generated.

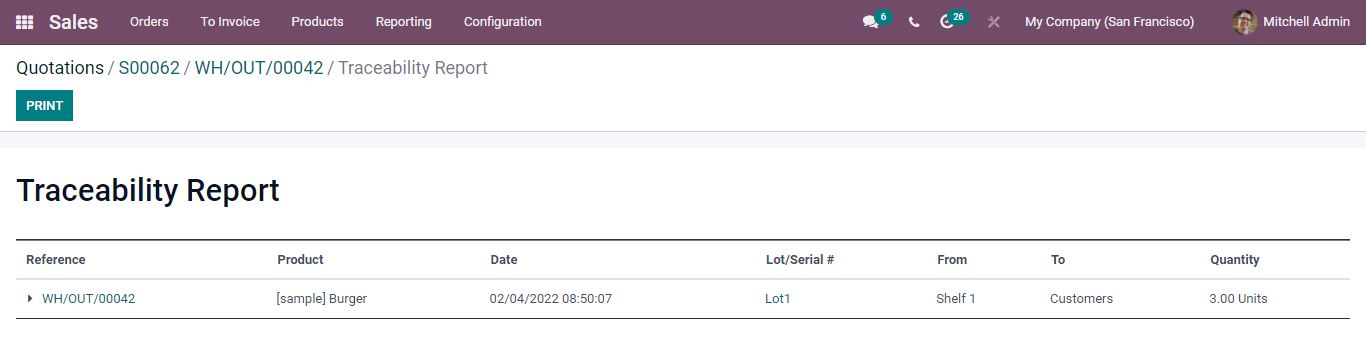

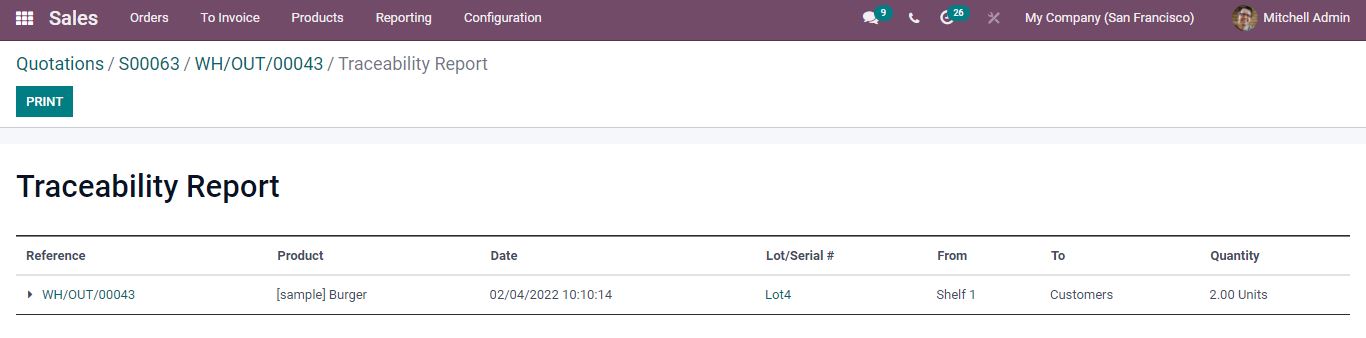

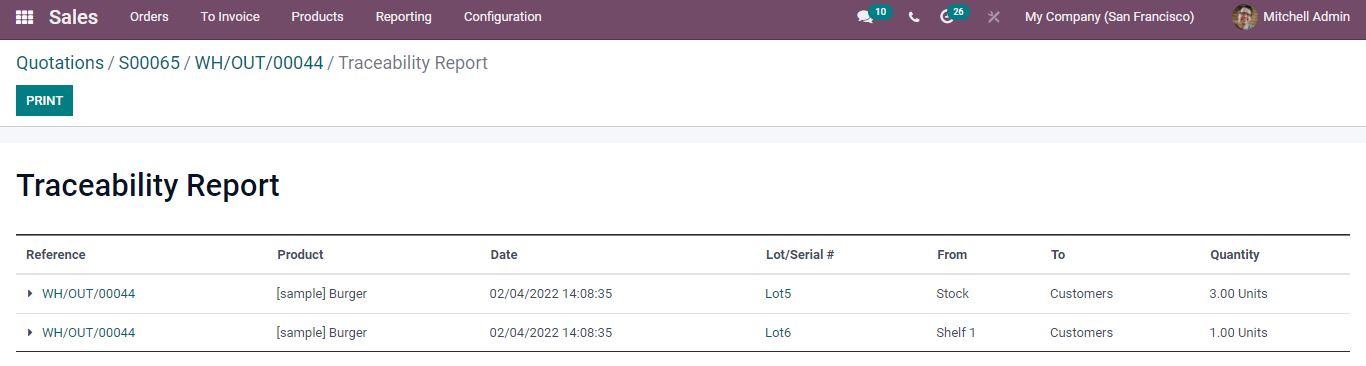

After validating a smart tab appears for tracing the products. Opening the Traceability tab the product’s movement is described.

The traceability report shows the reference, product, date, lot number, location and the number of quantities sold. As a result, the first purchased product is sold first (First In First Out – FIFO).

- Last In First Out (LIFO)

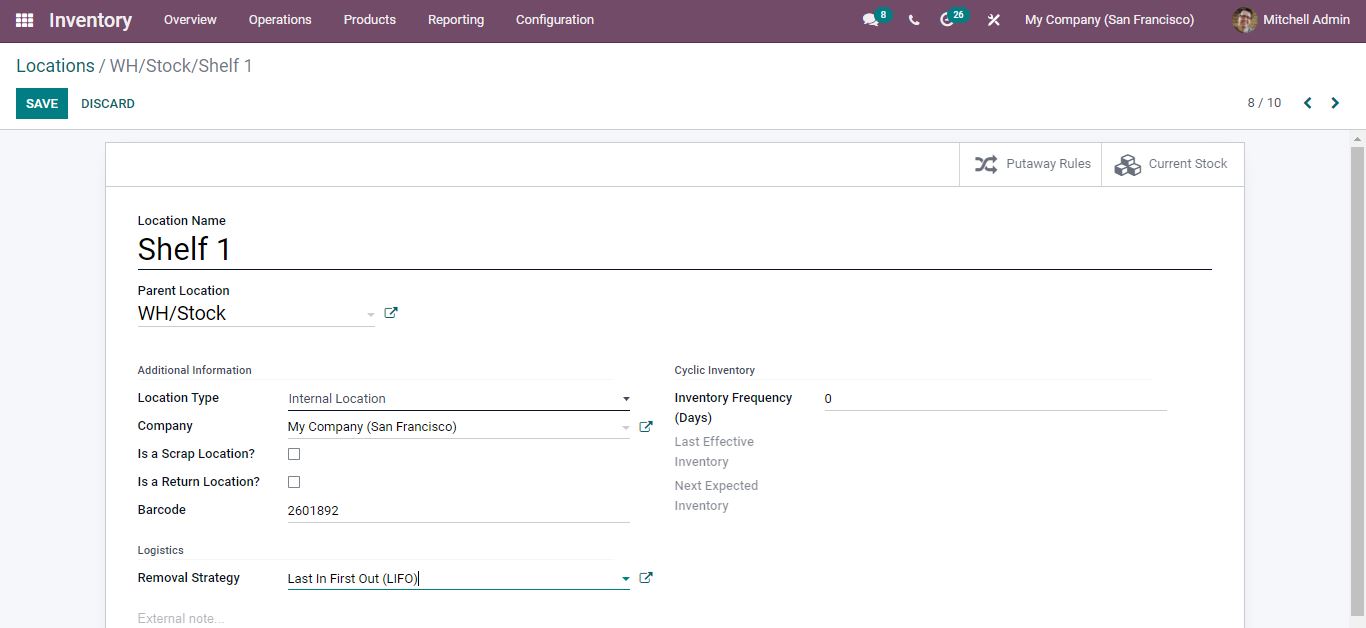

Select a location and choose the removal strategy as Last in First Out.

Purchase a product and after confirming the order allot the lot numbers for the products before validating.

Again make another purchase order for the same product and give the lot numbers.

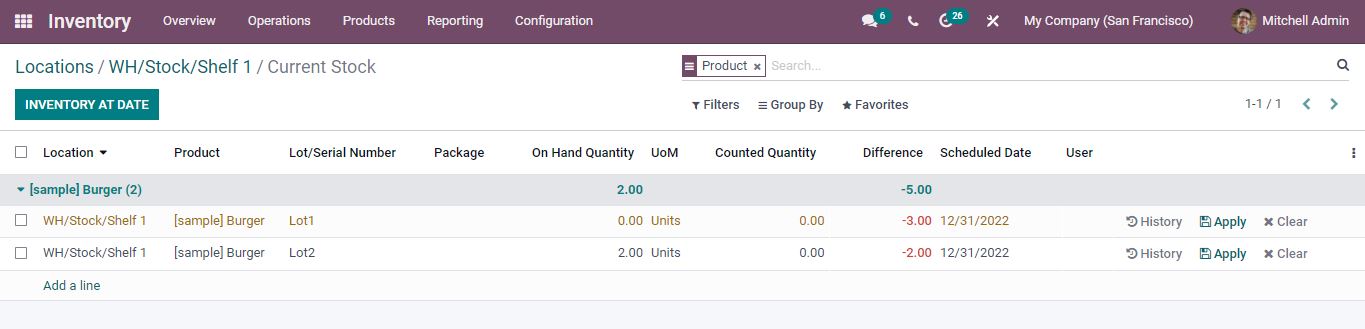

After confirming the operations validate the purchase and then open the locations and the stocks will be added to the Locations of the related Product under the current stock.

To know the stock movement in the inventory, create a sales order for the same product. After confirming the order a delivery tab appears to validate. Once it is validated traceability tab is opened to know the product’s movement.

Opening the inventory locations current stock, all the stock details in that location can be viewed. As a result, the last purchased product is sold first (Last In First Out – LIFO).

- Closest Location

Open a location and change the removal strategy to Closest Location.

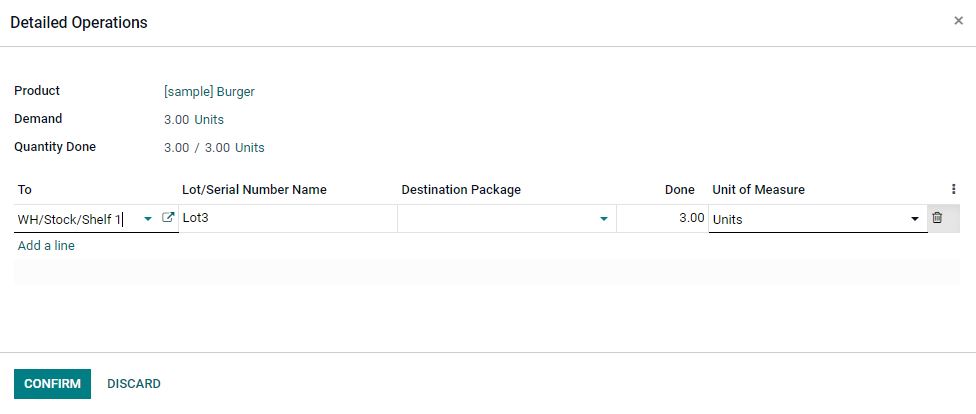

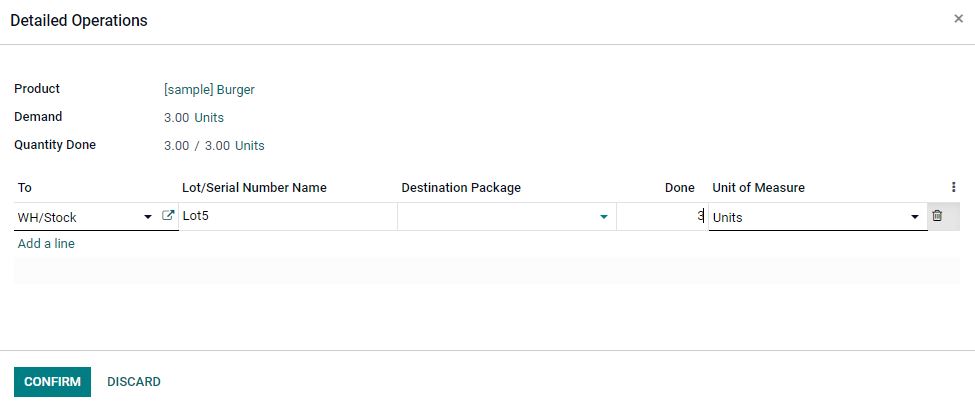

Create a purchase order for the product with three quantities and once the products are received give lot numbers.

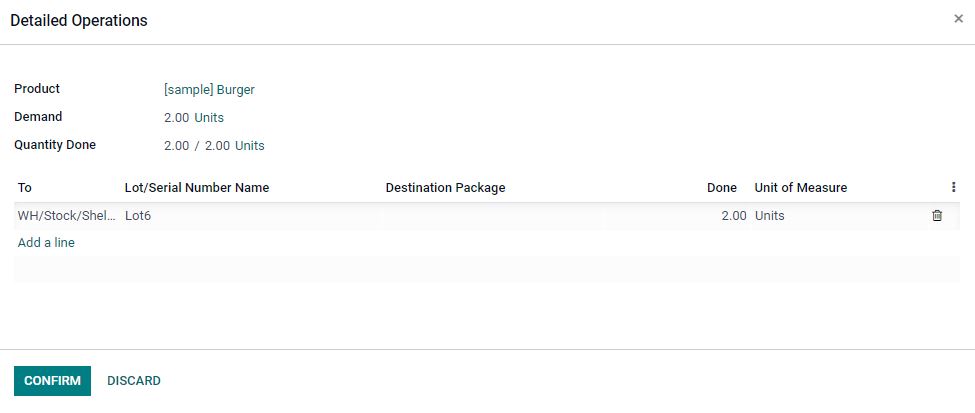

Again create another purchase order for the same product with quantity two and allot lot numbers.

Here the location selected is different and it is close to the previous warehouse location. Now create a sales order for the product with four quantities. After confirming and validating the traceability tab appears and shows the stock movement. The traceability Report shows from where your stocks are removed along with the number of quantities.

Are you ready to implement an effective ERP solution for a productive business? Reach out to us at www.infintor.com